|

|

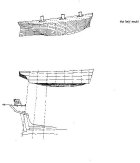

Most Nova Scotian built square-rigged vessels were designed by a master builder or the foreman of the shipyard, not by a naval architect. The design of a vessel was usually a compromise between a shape conducive to speed and providing sufficient cargo capacity. If it was particularly successful, it could be used again, often with slight modifications made to accommodate the needs of the shipowner.

The master builder did not follow an architect's plans, but created a half model of a the ship from which to work, often on a scale of 3/8" to the foot, but not always. This model was carved out of many horizontal layers of wood pegged together to form a block. These layers provided the builder with the shape of the vessel at various depths or was measured, from its flat side to its curved edge, at equidistant intervals running the length of the model. This vertical center line running measurements represented the distance on the actual vessel from the parallel with the keel, to the insides of the vessel's frames. When scaled up to full size and potted on the floor of a shed or "mould loft", they created a pattern from which the shape and measurements of each of the vessel's frames could be taken.

The master builder did not follow an architect's plans, but created a half model of a the ship from which to work, often on a scale of 3/8" to the foot, but not always. This model was carved out of many horizontal layers of wood pegged together to form a block. These layers provided the builder with the shape of the vessel at various depths or was measured, from its flat side to its curved edge, at equidistant intervals running the length of the model. This vertical center line running measurements represented the distance on the actual vessel from the parallel with the keel, to the insides of the vessel's frames. When scaled up to full size and potted on the floor of a shed or "mould loft", they created a pattern from which the shape and measurements of each of the vessel's frames could be taken.

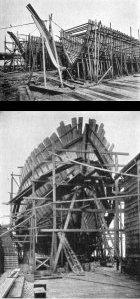

Shipyards were located next to bodies of water large enough and deep enough for the launching of a vessel. The site on which

the ship was constructed had to slope gradually down to the waters edge, in order that the vessel could slide into the water under the force of gravity at the time of launch. During construction the vessel was supported by bed logs, huge timbers set into the ground, running parallel to the waters edge and extending up the slope for a distance slightly greater than the length of the ship under construction. These logs were flattened on their upper surfaces and usually covered with heavy planking, 3" to 4" thick, which created a floor upon which to build the ship, and prevented it from sinking into the mud under its own weight. On top of this arrangement were placed the blocks upon which the keel would rest. These raised the keel three to four feet off the ground, allowing men room to work underneath the ship.

the ship was constructed had to slope gradually down to the waters edge, in order that the vessel could slide into the water under the force of gravity at the time of launch. During construction the vessel was supported by bed logs, huge timbers set into the ground, running parallel to the waters edge and extending up the slope for a distance slightly greater than the length of the ship under construction. These logs were flattened on their upper surfaces and usually covered with heavy planking, 3" to 4" thick, which created a floor upon which to build the ship, and prevented it from sinking into the mud under its own weight. On top of this arrangement were placed the blocks upon which the keel would rest. These raised the keel three to four feet off the ground, allowing men room to work underneath the ship.

Hardwood was usually used for the keel (local yellow or black birch). In a small vessel, a single piece might suffice, but in larger vessels huge timbers were bolted together. While the keel was being laid, workmen built and shaped the stern and sternpost and the frames of the vessel. Again, in a small boat, a single piece of timber could be bent to form a frame, but in a large vessel several pieces were used, fastened securely together with treenails and dowels. These timbers were often selected and cut from local woodlots according to the suitability of their natural shapes to a specific section of frame. They were shaped more precisely in the shipyard, using a broadaxe and adze, and following the natural curvature of their grain as much as possible, in continuity with the intended lines of the vessel.

Finished frames were "raised" by trackles and poles along the length of the keel, at even spacings and parallel to each other. The floor frames were bolted to the keel, and the stern and sternpost fitted in place, using "scarphs" and aprons for extra support. Since the joints were staggered as much as possible on the vertical plane, in order to avoid creating a structural weakness in the ship. It was said that timber which had been seasoned made a stronger vessel. Sometimes frames were allowed to stand unplanked in a shipyard for month.

When the skeleton of the vessel was complete, she was said to be in frame, and the addition of strengthening timbers could begin. The keelson, a heavy timber, was laid over top of the floor frames, running the length of the keel, and bolted to it through the frames. Inside the hull, the "ceiling" or inner planking was bolted to the frames, running in a "fore and aft" direction to give further strength to the hull and to protect the frames from the ship's cargo. This planking could be 9" thick in the ship's bottom, ranging to 5" thick above the lower deck. When the ceiling was in place up to the lower deck, the shelf and clamp timbers were bolted to the vertical frames, running perpendicular to them, down the length of the vessel. The number of these "shelves" depended upon the number of decks in a particular vessel. A square rigged vessel of 500 to 1200 tons usually had two decks, and anything larger, three.

When the skeleton of the vessel was complete, she was said to be in frame, and the addition of strengthening timbers could begin. The keelson, a heavy timber, was laid over top of the floor frames, running the length of the keel, and bolted to it through the frames. Inside the hull, the "ceiling" or inner planking was bolted to the frames, running in a "fore and aft" direction to give further strength to the hull and to protect the frames from the ship's cargo. This planking could be 9" thick in the ship's bottom, ranging to 5" thick above the lower deck. When the ceiling was in place up to the lower deck, the shelf and clamp timbers were bolted to the vertical frames, running perpendicular to them, down the length of the vessel. The number of these "shelves" depended upon the number of decks in a particular vessel. A square rigged vessel of 500 to 1200 tons usually had two decks, and anything larger, three.

Upon the shelf timbers the deck beams rested, straddling the ship at right-angles to the keel below. The deck beams were fitted with heavy knees, or braces, at their junction with the vertical frames. In the earlier years of shipbuilding in Nova Scotia the knees were often formed of a single piece of wood, taken from the tree where the trunk meets the roots at a convenient right-angle, and providing a natural strength.

A vessel was planked from the keel upwards, with slightly thicker planking being used below the waterline. Planks were steamed in a "steam box" at the shipyard, making them more pliable, and then twisted and bent as swiftly as possible into the shapes necessary to fit them onto the frame of the vessel. They were attached using treenails, iron or copper bolts, or a combination of the three. Each was believed to have its own merits. Treenails, being of wood, could be compressed slightly before being driven in, and would swell to a tight fit once in the water. They were also said to "work the ship", providing a less unyielding resistance to its movements than iron. On the other hand, iron bolts were believed to hold very securely when rusted. Bolts or treenails were driven right through the planking, frames and ceiling into the pre-bored holes of slightly smaller diameter than that of the fastening to ensure a tight fit. The butt-ends of all planks met on the frames and were distributed "out of line" across the hull, to avoid weakening its structure.

|